obdlaunch

AUTOOL AST618 12V Vehicles Pulsating Brake Oil Exchanger Four Clutch Slave Cylinders Automotive Brake Extractor Oil Pump Machine

AUTOOL AST618 12V Vehicles Pulsating Brake Oil Exchanger Four Clutch Slave Cylinders Automotive Brake Extractor Oil Pump Machine

Couldn't load pickup availability

AUTOOL AST618 12V Vehicles Pulsating Brake Oil Exchanger Four Clutch Slave Cylinders Automotive Brake System Tools

For Applicable to European, American and Asian car models.Four sub-pumps changing oil at the same time, it is fast and labour-saving. Adjustable pulse oil change, which can effectively clean the pipeline and change the oil more thoroughly.Powerful recovery function, it can quickly recover used brake fluid at the same time.The air inlet port has a water separating and filtering device, which can separate the moisture in the air, avoid it mixing with the oil, and ensure the quality.

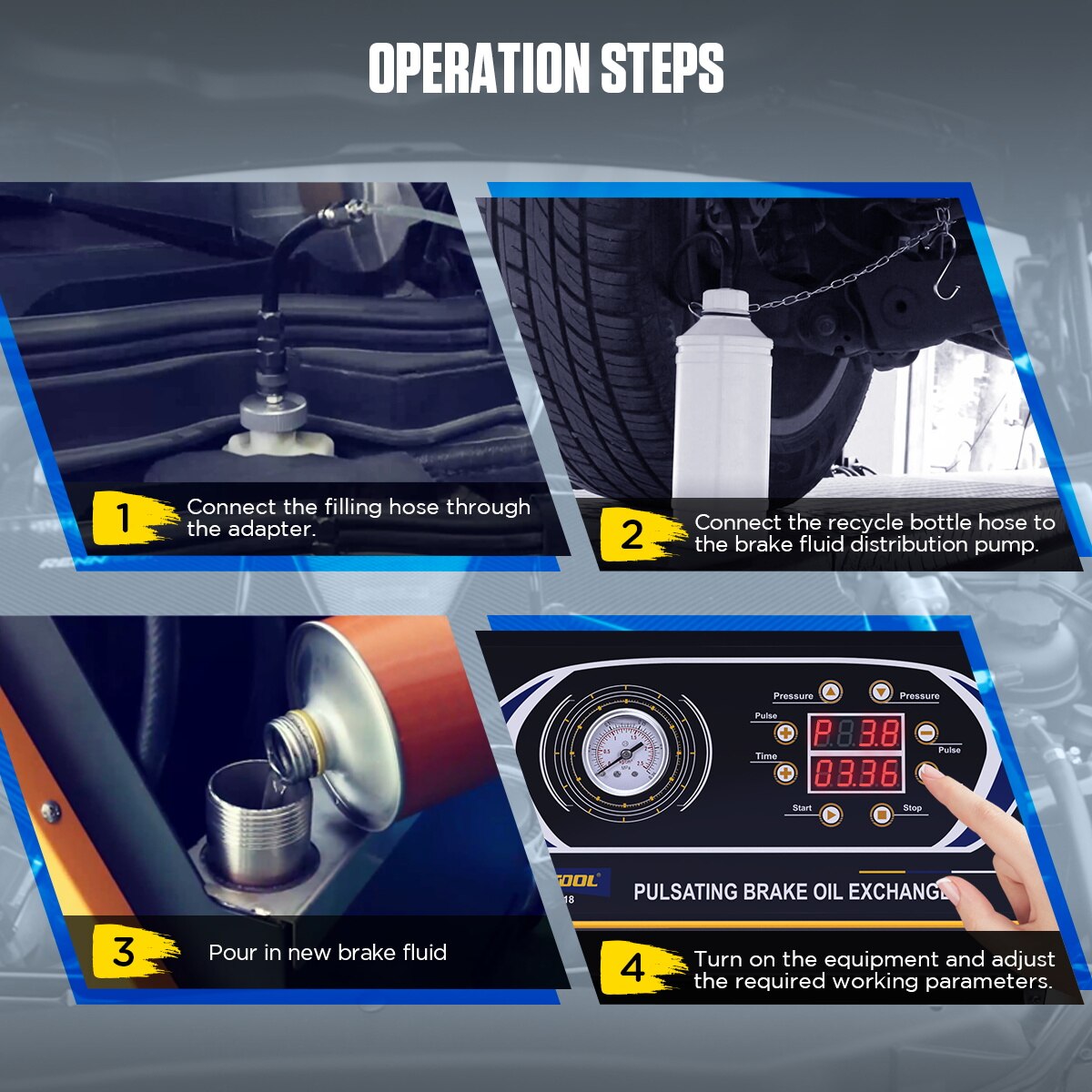

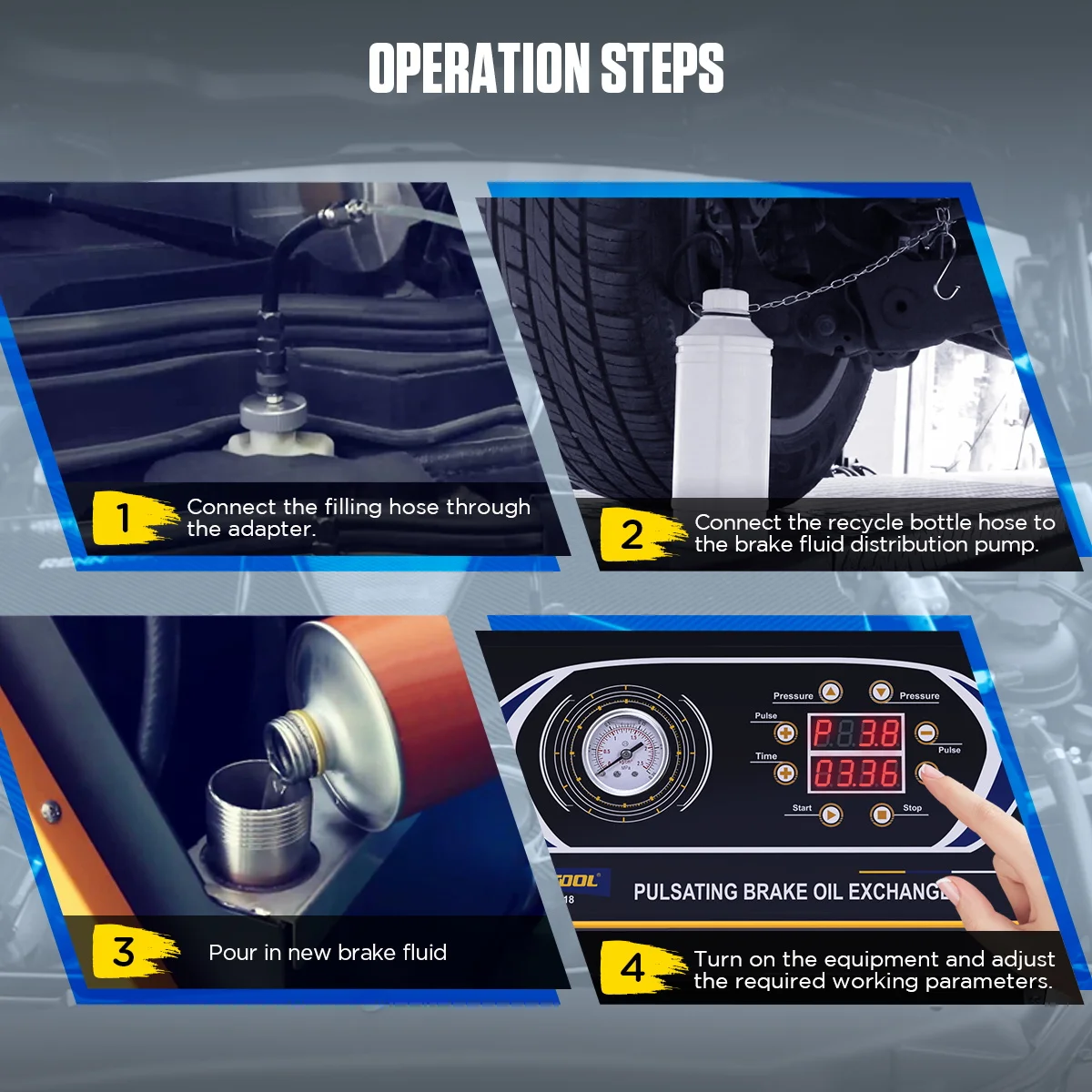

Operation steps:

Note: no need to start the vehicle for the operation.

1. Raise the car to a suitable height so the drive wheels are not on the ground.

2. Connect the four oil pots of the device to the car brake cylinder, and loosen the exhaust screw of the brake cylinder to ensure that oil flows out.

3. Pour in 5L new brake fluid from the fuel filler port of the equipment, and find the matching model connector to connect to the fuel filler of the brake master cylinder.

4. Connect to 12V car power and turn on the power switch button.

5. Press the Vacuum Switch button.

6. Press the Fuel Switch button to change the brake fluid.

7. During the oil changing process, look at the car brake oil tank mouth, if the refuel is too slow, press the acceleration switch button on the device to accelerate refueling; if it’s too fast, press the deceleration switch button to slow down.

8. After the oil change is completed, the used oil in the tank of the equipment must be drained clean. If it’s not emptied clean, the vacuum pump will be damaged and the oil change operation cannot be performed.

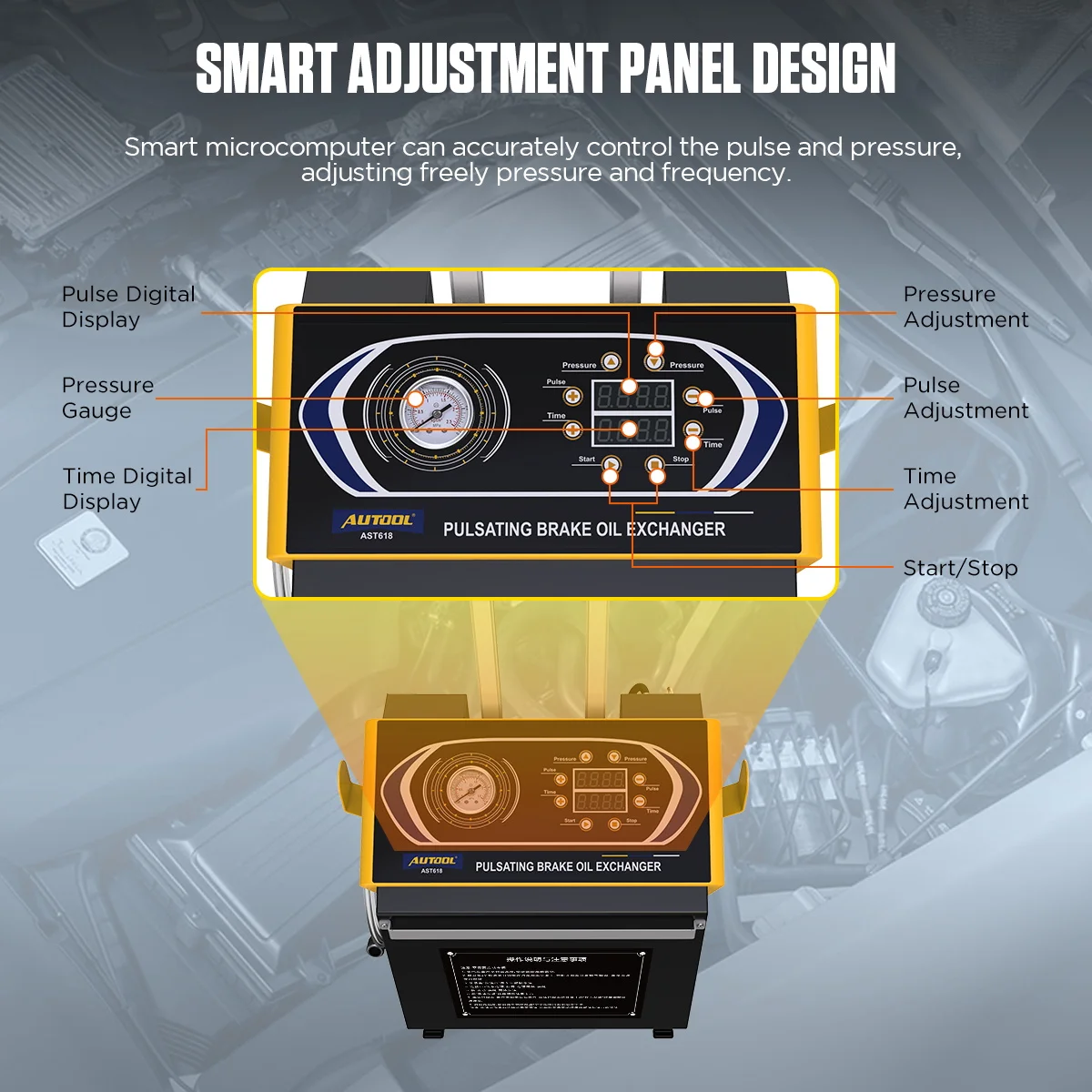

How to adjust working pressure correctly?

When the device is out of factory, the working pressure of the pressure regulator is set to 1~1.5 bar, to ensure that the liquid storage chamber does not deform while changing liquid, thereby ensuring the tightness of the secondary sealing ring. In addition, it is also feasible to exhaust or change the liquid at a lower working pressure by adjusting the pressure and the size switch. In special circumstances, while operating under a higher working pressure, be aware of the excessive pressure adjustment, which may damage the brake master cylinder of the brake system.

Packing List:

Notice:Please check each connection if there is any leak, when changing oil, and whether the connecting hose is damaged, to keep the new oil filler port clean.

Share